Talking about materials to make electrical cabling, aluminum, and copper are two of the most common materials used in production. Two of them can conduct electricity.

Although both metals share the same ability, aluminum and copper still have several distinctive characteristics.

To find out which one is better at producing electricity and the advantages and disadvantages of using both metals, read on the elaboration about aluminum vs. copper wire below.

Aluminum VS Copper Wire

Both aluminum and copper wiring are conductive metals and the most common materials used in the production of electrical items. However, aluminum has a higher ratio of thermal expansion and is not as solid as copper. That being said, there are still benefits to using aluminum cabling.

A residential home or commercial building uses aluminum cabling to save expenses in the construction process. Aside from that, aluminum’s application is way easier than copper wiring because aluminum is more flexible.

Although aluminum is more affordable than copper wiring, many still prefer using copper because of its higher tensile strength than its counterpart. The high tensile strength can prevent breakage during installation. Aside from that, copper cabling also has a lower ratio of thermal expansion.

Copper vs. Aluminum Wire Size

Aluminum VS copper wire, which to use? Both metals have their own advantages and disadvantages. Copper has several benefits. Aside from being able to be applied in many items and having tensile strength higher than aluminum, they also have a small size.

In tight areas, smaller wires are working correctly. Hence, it becomes the main reason why copper is the best option when installing a receptacle or a switch.

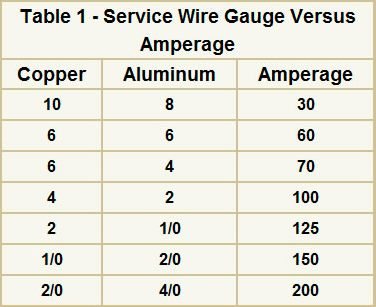

As for the aluminum wire, although they are also a good conductor and quite light, their size is much larger than copper. To conduct electricity, a large conductor must be upgraded to help circuits that have the same ampacity.

Copper VS Aluminum Wire Current Capacity

Current capacity is the main factor in deciding whether to use copper or aluminum wire in electrical applications. In terms of volume, copper wire provides better current capacity. Nevertheless, aluminum is way better than copper when it comes to weight capacity.

When both metals are still raw, aluminum is 70% much lighter than copper. Meanwhile, for wires, aluminum can be 60% way lighter than copper.

In the conclusion of aluminum vs. copper wire above, aluminum and copper wires are substantially common cable materials for industrial, commercial, and domestic projects. In terms of price, aluminum is more affordable and easier to work with. Besides that, aluminum is more flexible than copper wire and to be applied easily in small places.

However, the copper wire becomes the most preferred material for tensile strength since it is much stronger and can avoid breakage during installation. The optimal choice of cable entirely depends on the project, area, situation, budget, and safety specifications.